Filters

Host (770489)

Bovine (1090)Canine (20)Cat (408)Chicken (1642)Cod (2)Cow (333)Crab (15)Dog (524)Dolphin (2)Duck (13)E Coli (239125)Equine (7)Feline (1864)Ferret (306)Fish (125)Frog (55)Goat (36847)Guinea Pig (752)Hamster (1376)Horse (903)Insect (2053)Mammalian (512)Mice (6)Monkey (622)Mouse (96367)Pig (197)Porcine (70)Rabbit (360490)Rat (11713)Ray (55)Salamander (4)Salmon (15)Shark (3)Sheep (4247)Snake (4)Swine (301)Turkey (57)Whale (3)Yeast (5339)Zebrafish (3022)Isotype (157212)

IgA (13691)IgA1 (946)IgA2 (319)IgD (1964)IgE (5651)IgG (87493)IgG1 (16666)IgG2 (1330)IgG3 (2729)IgG4 (1695)IgM (22194)IgY (2534)Label (239657)

AF488 (2465)AF594 (662)AF647 (2324)ALEXA (11546)ALEXA FLUOR 350 (255)ALEXA FLUOR 405 (260)ALEXA FLUOR 488 (672)ALEXA FLUOR 532 (260)ALEXA FLUOR 555 (274)ALEXA FLUOR 568 (253)ALEXA FLUOR 594 (299)ALEXA FLUOR 633 (262)ALEXA FLUOR 647 (607)ALEXA FLUOR 660 (252)ALEXA FLUOR 680 (422)ALEXA FLUOR 700 (2)ALEXA FLUOR 750 (414)ALEXA FLUOR 790 (215)Alkaline Phosphatase (825)Allophycocyanin (32)ALP (387)AMCA (80)AP (1160)APC (15226)APC C750 (13)Apc Cy7 (1248)ATTO 390 (3)ATTO 488 (6)ATTO 550 (1)ATTO 594 (5)ATTO 647N (4)AVI (52)Beads (235)Beta Gal (2)BgG (1)BIMA (6)Biotin (27799)Biotinylated (1810)Blue (708)BSA (878)BTG (46)C Terminal (688)CF Blue (19)Colloidal (22)Conjugated (29282)Cy (163)Cy3 (390)Cy5 (2041)Cy5 5 (2469)Cy5 PE (1)Cy7 (3638)Dual (170)DY549 (3)DY649 (3)Dye (1)DyLight (1430)DyLight 405 (7)DyLight 488 (216)DyLight 549 (17)DyLight 594 (84)DyLight 649 (3)DyLight 650 (35)DyLight 680 (17)DyLight 800 (21)Fam (13)Fc Tag (8)FITC (30173)Flag (207)Fluorescent (146)GFP (580)GFP Tag (179)Glucose Oxidase (59)Gold (511)Green (580)GST (721)GST Tag (326)HA Tag (439)His (629)His Tag (504)Horseradish (550)HRP (12993)HSA (249)iFluor (16571)Isoform b (31)KLH (88)Luciferase (102)Magnetic (260)MBP (344)MBP Tag (93)Myc Tag (409)OC 515 (1)Orange (78)OVA (104)Pacific Blue (213)Particle (64)PE (33605)PerCP (8438)Peroxidase (1379)POD (11)Poly Hrp (94)Poly Hrp40 (13)Poly Hrp80 (3)Puro (32)Red (2440)RFP Tag (62)Rhodamine (607)RPE (910)S Tag (194)SCF (184)SPRD (351)Streptavidin (55)SureLight (77)T7 Tag (97)Tag (4800)Texas (1249)Texas Red (1231)Triple (10)TRITC (1401)TRX tag (90)Unconjugated (2106)Unlabeled (218)Yellow (84)Pathogen (489613)

Adenovirus (8687)AIV (317)Bordetella (25038)Borrelia (18284)Candida (17817)Chikungunya (639)Chlamydia (17666)CMV (121399)Coronavirus (5949)Coxsackie (859)Dengue (2872)EBV (1512)Echovirus (215)Enterovirus (677)Hantavirus (259)HAV (910)HBV (2098)HHV (876)HIV (7887)hMPV (302)HSV (2359)HTLV (635)Influenza (22155)Isolate (1208)KSHV (396)Lentivirus (3545)Lineage (3025)Lysate (127759)Marek (94)Measles (1169)Parainfluenza (1692)Poliovirus (3033)Poxvirus (81)Rabies (1530)Reovirus (536)Retrovirus (1069)Rhinovirus (511)Rotavirus (5358)RSV (1786)Rubella (1072)SIV (279)Strain (67791)Vaccinia (7231)VZV (667)WNV (369)Species (2989665)

Alligator (10)Bovine (159807)Canine (120802)Cat (13121)Chicken (113988)Cod (1)Cow (2031)Dog (12758)Dolphin (21)Duck (9606)Equine (2012)Feline (1019)Ferret (259)Fish (12875)Frog (1)Goat (90541)Guinea Pig (87959)Hamster (36959)Horse (41295)Human (958131)Insect (653)Lemur (119)Lizard (24)Monkey (110990)Mouse (471934)Pig (26233)Porcine (131969)Rabbit (127882)Rat (349252)Ray (443)Salmon (348)Seal (8)Shark (29)Sheep (105151)Snake (12)Swine (519)Toad (4)Turkey (244)Turtle (75)Whale (45)Zebrafish (535)Technique (5595867)

Activation (170412)Activity (10776)Affinity (44632)Agarose (2604)Aggregation (199)Antigen (135466)Apoptosis (27400)Array (2021)Blocking (71764)Blood (8529)Blot (10966)ChiP (814)Chromatin (6286)Colorimetric (9866)Control (80077)Culture (3219)Cytometry (5475)Depletion (56)DNA (172524)Dot (233)EIA (1039)Electron (6275)Electrophoresis (254)Elispot (1294)Enzymes (52762)Exosome (4280)Extract (1089)Fab (2229)FACS (43)FC (80588)Flow (6662)Fluorometric (1407)Formalin (97)Frozen (2669)Functional (707)Gel (2480)HTS (136)IF (12906)IHC (16566)Immunoassay (1589)Immunofluorescence (4119)Immunohistochemistry (72)Immunoprecipitation (68)intracellular (5602)IP (2854)iPSC (259)Isotype (8804)Lateral (1587)Lenti (319416)Light (37309)Microarray (47)MicroRNA (4835)Microscopy (52)miRNA (88042)Monoclonal (524774)Multi (3844)Multiplex (302)Negative (4255)PAGE (2521)Panel (1633)Paraffin (2587)PBS (20266)PCR (9)Peptide (276250)PerCP (13759)Polyclonal (2752395)Positive (6334)Precipitation (61)Premix (130)Primers (3464)Probe (2630)Profile (229)Pure (7818)Purification (15)Purified (78237)Real Time (3042)Resin (2975)Reverse (2438)RIA (460)RNAi (17)Rox (1023)RT PCR (6608)Sample (2666)SDS (1524)Section (2895)Separation (86)Sequencing (122)Shift (22)siRNA (319447)Standard (42464)Sterile (10168)Strip (1863)Taq (2)Tip (1172)Tissue (42843)Tube (3305)Vitro (3577)Vivo (980)WB (2515)Western Blot (10683)Tissue (2016611)

Adenocarcinoma (1075)Adipose (3463)Adrenal (657)Adult (4883)Amniotic (65)Animal (2453)Aorta (436)Appendix (89)Array (2021)Ascites (4737)Bile Duct (20)Bladder (1675)Blood (8529)Bone (27361)Brain (31212)Breast (10918)Calvaria (28)Carcinoma (13497)cDNA (58548)Cell (413580)Cellular (9348)Cerebellum (700)Cervix (232)Child (1)Choroid (19)Colon (3911)Connective (3602)Contaminant (3)Control (80077)Cord (661)Corpus (148)Cortex (698)Dendritic (1849)Diseased (265)Donor (1359)Duct (861)Duodenum (643)Embryo (425)Embryonic (4586)Endometrium (466)Endothelium (1424)Epidermis (166)Epithelium (4224)Esophagus (716)Exosome (4280)Eye (2033)Female (475)Frozen (2669)Gallbladder (155)Genital (5)Gland (3435)Granulocyte (8984)Heart (6851)Hela (408)Hippocampus (325)Histiocytic (74)Ileum (201)Insect (4880)Intestine (1945)Isolate (1208)Jejunum (175)Kidney (8079)Langerhans (283)Leukemia (21570)Liver (17342)Lobe (835)Lung (6074)Lymph (1208)Lymphatic (639)lymphocyte (22588)Lymphoma (12791)Lysate (127759)Lysosome (2813)Macrophage (31820)Male (1617)Malignant (1467)Mammary (1987)Mantle (1042)Marrow (2210)Mastocytoma (3)Matched (11710)Medulla (156)Melanoma (15525)Membrane (105788)Metastatic (3575)Mitochondrial (160328)Muscle (37425)Myeloma (748)Myocardium (11)Nerve (6399)Neuronal (17035)Node (1206)Normal (9486)Omentum (10)Ovarian (2511)Ovary (1173)Pair (47185)Pancreas (2843)Panel (1633)Penis (64)Peripheral (1910)Pharynx (122)Pituitary (5421)Placenta (4049)Prostate (9438)Proximal (318)Rectum (316)Region (202210)Retina (956)Salivary (3119)Sarcoma (6946)Section (2895)Serum (24915)Set (167649)Skeletal (13634)Skin (1882)Smooth (7574)Spinal (424)Spleen (2292)Stem (8898)Stomach (925)Stroma (49)Subcutaneous (47)Testis (15396)Thalamus (127)Thoracic (60)Throat (40)Thymus (2988)Thyroid (14149)Tongue (144)Total (10150)Trachea (227)Transformed (174)Tubule (48)Tumor (76982)Umbilical (208)Ureter (73)Urinary (2467)Uterine (303)Uterus (414)Scaling Up AAV Manufacturing : Challenges and Opportunities

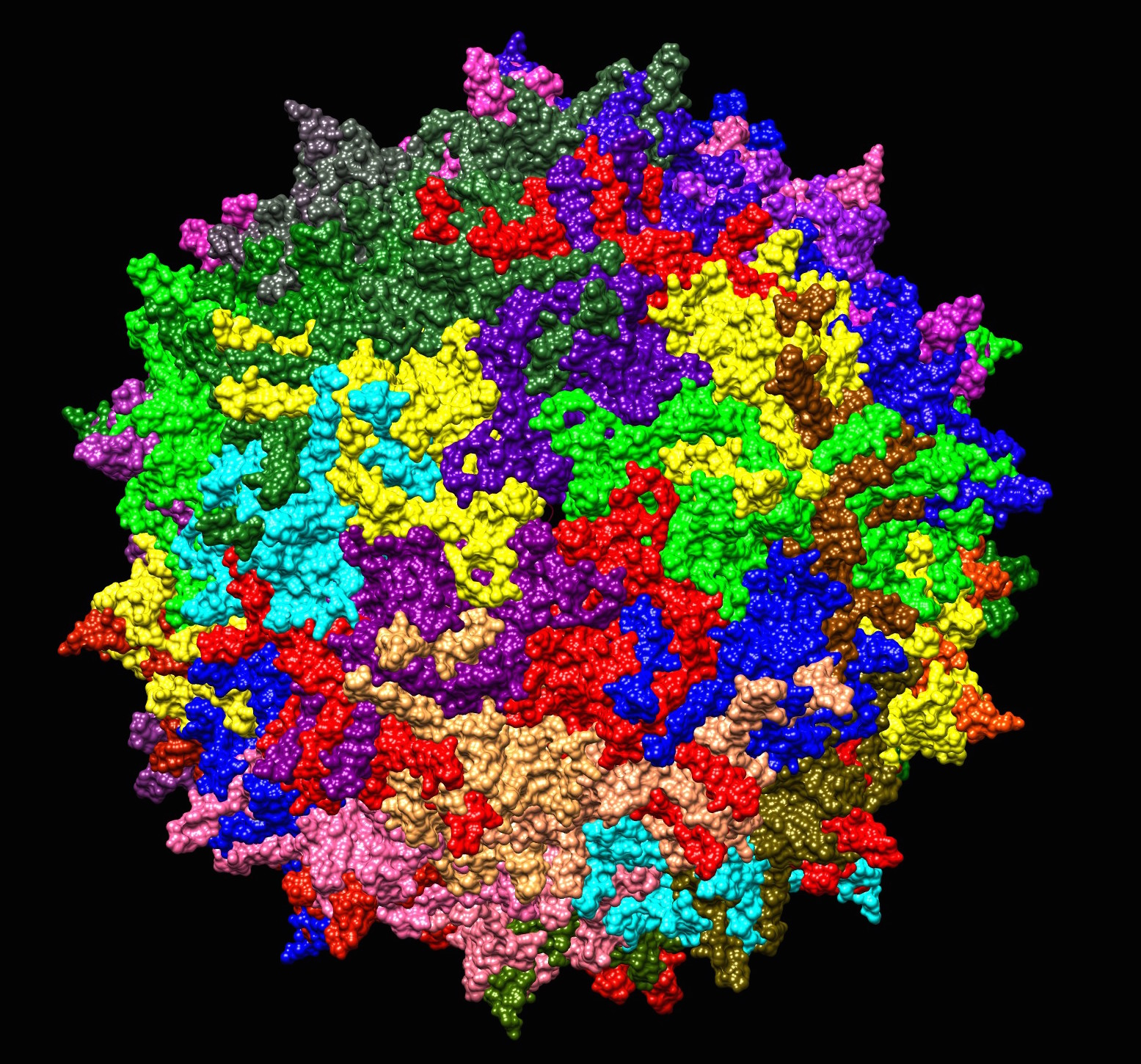

Adeno-Associated Virus (AAV) vectors have become one of the most important tools in gene therapy research and biomanufacturing. They are widely used for in-vivo delivery of therapeutic genes, CRISPR components, reporter systems, and functional studies in both academic and industrial settings. As interest in gene therapy continues to grow, the need for scalable, reliable, and high-yield AAV production has become a major priority in the biotechnology world.

However, scaling up AAV manufacturing is not a simple task. AAVs are complex biological products, and maintaining vector quality, purity, and biological activity becomes more challenging as production volumes increase. This article explores the main challenges and key opportunities shaping AAV scale-up in 2025.

Genprice

Scientific Publications

Scaling Up AAV Manufacturing : Challenges and Opportunities

1. The Growing Demand for AAV Vectors

AAV (Wikipdia) has become the preferred vector in many gene therapy research programs because :

- It shows low immunogenicity.

- It supports long-term gene expression.

- It has many serotypes for tissue-specific targeting.

- It is compatible with in-vivo gene delivery.

- It is relatively safe and well-characterized.

Because of these advantages, researchers increasingly use AAV for :

- Preclinical models.

- Gene editing delivery.

- Functional genomics.

- In-vivo CRISPR studies.

- Reporter gene work.

- Therapeutic development pipelines.

As demand grows, labs need production systems that can generate large batches of AAV while preserving consistency and quality.

2. Challenges in Scaling Up AAV Manufacturing

📌 Challenge 1 : Maintaining Vector Quality at Large Volumes

Producing AAV at small scale (e.g., 10–50 mL) is relatively straightforward, but scaling to liters introduces many variables :

- Loss of vector potency.

- Lower full-to-empty capsid ratio.

- Increased impurities.

- Changes in cell metabolism or stress.

- Maintaining consistent quality is one of the most difficult obstacles in AAV manufacturing.

📌 Challenge 2 : Low Yields and Inefficient Packaging

AAV production requires :

- Efficient transfection (in triple-transfection systems).

- High metabolic activity from producer cells.

- Proper folding and assembly of capsids.

- Accurate packaging of genomes into capsids.

As culture vessels increase in size, transfection efficiency often declines. This leads to more empty capsids and lower biologically active vector yields.

📌 Challenge 3 : Purification Complexity

AAV purification is one of the biggest scale-up bottlenecks.

Common pain points include :

- Removing host cell DNA.

- Eliminating empty capsids.

- Achieving high purity without losing yield.

- Managing high buffer volumes.

- Maintaining consistent chromatography performance.

Process steps like density gradients (iodixanol) work well on bench scale but become impractical during industrial scale-up.

📌 Challenge 4 : High Cost of Goods (COGs)

AAV scale-up is expensive due to :

- Reagent costs (transfection reagents, media, plasmids).

- Specialized equipment.

- Purification columns and filtration systems.

- Process validation and QC assays.

Reducing cost while maintaining quality is a daily challenge for many labs and manufacturers.

3. Opportunities in AAV Manufacturing Scale-Up

Despite the challenges, scaling up AAV manufacturing opens many promising opportunities.

Opportunity 1 : New Production Platforms

Modern AAV production systems include :

- Suspension HEK293 cultures.

- Insect cell Sf9 systems (baculovirus-AAV production).

- Stable producer cell lines.

- Continuous bioprocessing.

- High-yield plasmid and packaging systems.

Switching from adherent cells to large-scale suspension bioreactors significantly improves scalability.

Opportunity 2 : Improved Upstream Transfection Technologies

Enhanced tools now enable:

- Higher transfection efficiency.

- Lower reagent usage.

- More consistent plasmid uptake.

- Better plasmid-to-cell ratios.

These improvements lead to higher full capsid percentages and increased overall productivity.

Opportunity 3 : Modern Chromatography Solutions

New AAV purification formats help overcome classical bottlenecks:

- Affinity resins specifically designed for AAV serotypes.

- Membrane-based purification systems.

- High-flow ultrafiltration devices.

These tools increase throughput and decrease process time while maintaining purity standards.

Opportunity 4 : Automated QC & Analytics

Automation now improves :

- Genome titer quantification.

- Capsid titer analysis.

- Empty/full capsid ratio measurement.

- Contamination and impurity detection.

- Host cell DNA and protein assays.

This reduces human error and improves batch-to-batch consistency.

Opportunity 5 : Cost Optimization at Large Scale

Scaling up opens the door to :

- Bulk reagent pricing.

- Lower cost per milliliter.

- More efficient purification.

- Larger vector batches from fewer runs.

This makes AAV production more accessible to small and medium-sized labs.